Page 1 of 2

Yet another "Steam engine backup" solution (simple&low tech)

Posted: Tue Nov 11, 2014 1:16 pm

by User_Name

I don't like the clock solution.

I want my steam engine to turn on in just two cases:

1) complete blackout due to full discharge

2) network surge/overload

This one does just that, without any energy bleed.

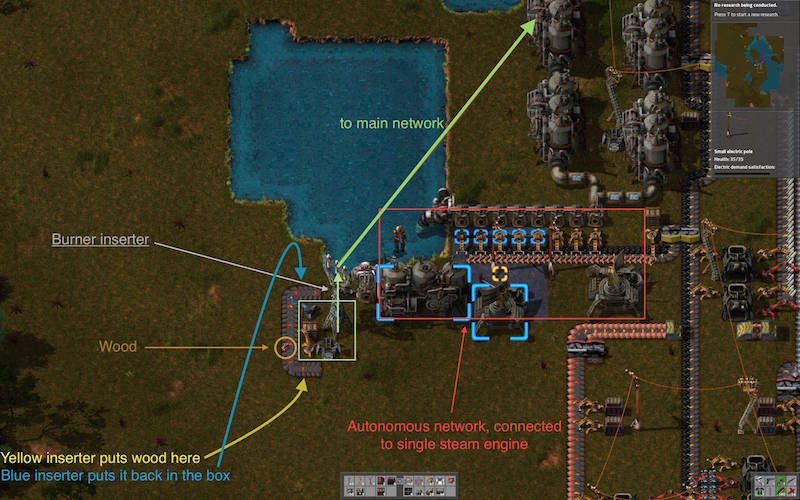

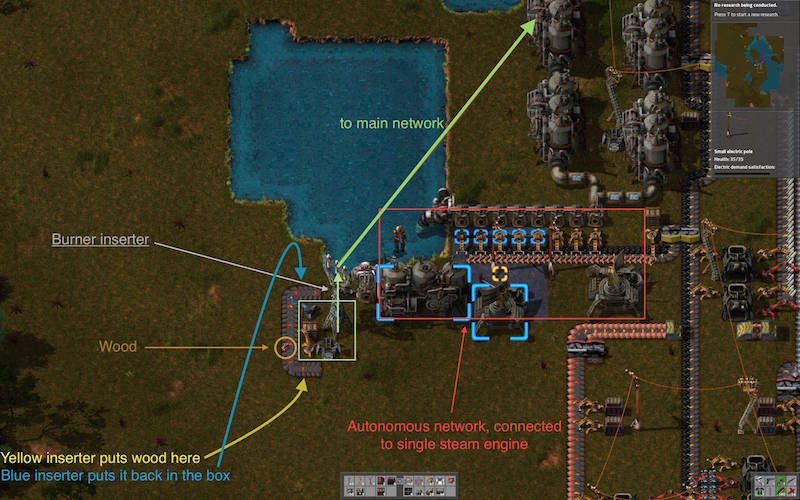

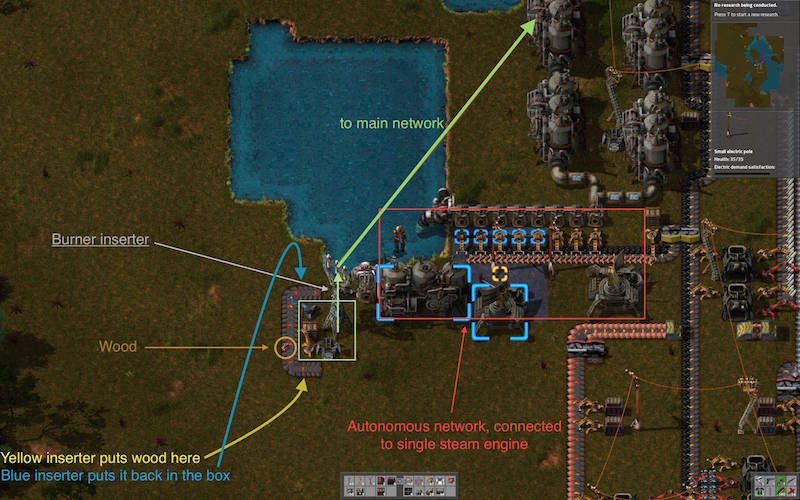

The inserters for my main steam engine are connected to separate network, powered by single "controller" engine.

Controler engine is out of fuel, thus inserters for my main engine are not powered, keeping it idle too.

There is a box with fuel (I use wood, because coal has too much energy for this purpose) and two inserters, powered from the main network. First inserter puts a piece of fuel on the belt, second one puts it back in the box.

In case of any problems with the main network second inserter starts skipping pieces which are already on the belt.

Controller engine springs to life and powers inserters for my main power plant, bringing it to full power in the matter of seconds.

I use two radars as a ballast to turn off my main power plant faster. Without any load single piece of wood can keep it powered for days.

Click to open 2880x1800

Update

Update: Check this thread for clean build:

My take on using steam as a backup. Works perfectly for me.

Re: Yet another "Steam engine backup" solution (simple&low t

Posted: Tue Nov 11, 2014 1:58 pm

by Boogieman14

So if there's one piece of wood on the belt and the burner inserter decides to take that to refuel itself, your entire base will end up without power?

Re: Yet another "Steam engine backup" solution (simple&low t

Posted: Tue Nov 11, 2014 2:11 pm

by User_Name

Burner inserter is fueled with coal, and with his average activity won't need refill for the next 100 years.

Longer/slower belts should be more reliable, but shorter/faster belts are more responsive/accurate, so I went with the shortest design possible.

Re: Yet another "Steam engine backup" solution (simple&low t

Posted: Tue Nov 11, 2014 2:56 pm

by chapium

Simple. I like it.

Re: Yet another "Steam engine backup" solution (simple&low t

Posted: Tue Nov 11, 2014 3:27 pm

by DerivePi

How long do you have before the inserters use up the power from one piece of wood? What are the connected radars for? Do they help you identify the problem?

Re: Yet another "Steam engine backup" solution (simple&low t

Posted: Tue Nov 11, 2014 3:59 pm

by User_Name

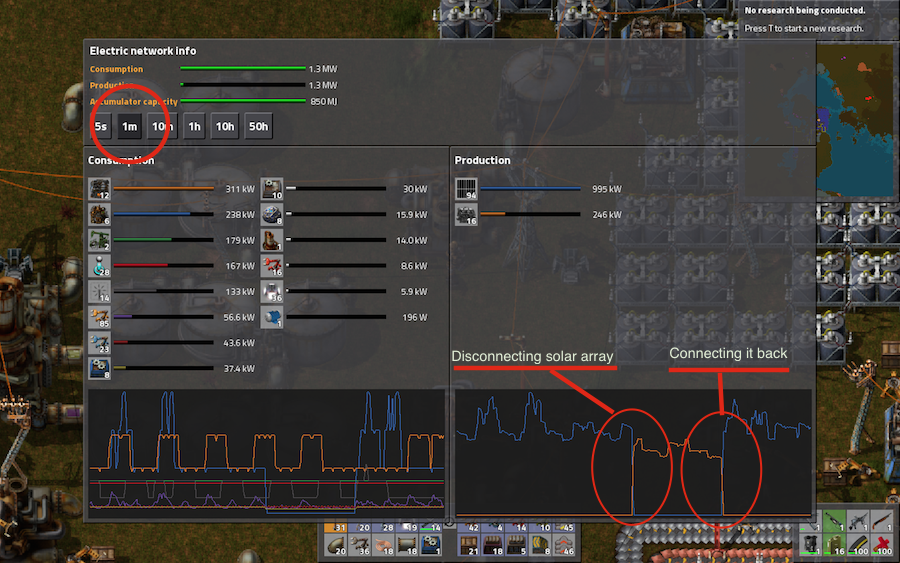

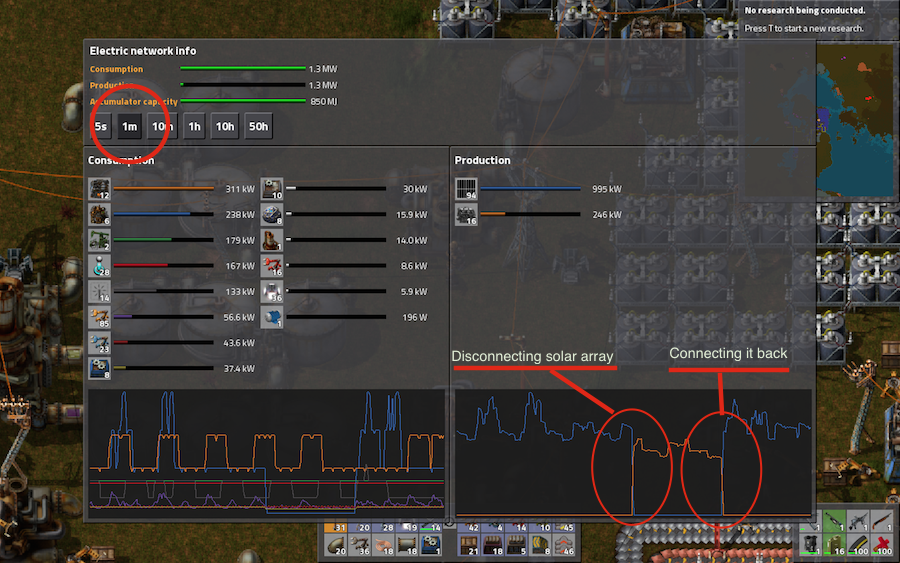

So far I'm impressed with the results. Steam engine kicks in a second or less after disconnecting solar panels/capacitors array, or when inserters show first signs of sluggishness.

I've added a pump after the boilers for faster cut-out, but can't really say if it helping. My factory is out of resources at the moment, thus consumption is fraction of what it once was.

Re: Yet another "Steam engine backup" solution (simple&low t

Posted: Tue Nov 11, 2014 4:03 pm

by User_Name

DerivePi wrote:How long do you have before the inserters use up the power from one piece of wood? What are the connected radars for? Do they help you identify the problem?

With 2 radars and a pump inserters go offline in 15-20 seconds. But boilers continue to produce power without fuel and water (pump blocks the pipe) for a whole minute after that due to my current low consumption level. Need to find some coal before I can resume testing.

Re: Yet another "Steam engine backup" solution (simple&low t

Posted: Wed Nov 12, 2014 3:06 pm

by User_Name

Full discharge at night:

http://imgur.com/EmRGe3l

As you can see, steam engine kicked in within a second after a full discharge, and got to the 100% performance in about 5 seconds. There was no blackout, just slowed down inserters.

The pits are the steam engine asking "Can I turn off now? How about now? Maybe now?".

Steam turned off just after solar panels got enough power to sustain the load.

I'm using a setup with a pump between boilers and engine to keep hot water in boilers ready (otherwise steam engine uses all hot water it could get after the fuel supply cut off)

Re: Yet another "Steam engine backup" solution (simple&low t

Posted: Wed Nov 12, 2014 3:23 pm

by User_Name

So, setup can be reduced to controller engine, two inserters and a single pump. There is no need to power fuel inserters from the controller network, pump does the job, and it is way more responsive.

Re: Yet another "Steam engine backup" solution (simple&low t

Posted: Thu Nov 13, 2014 1:31 am

by User_Name

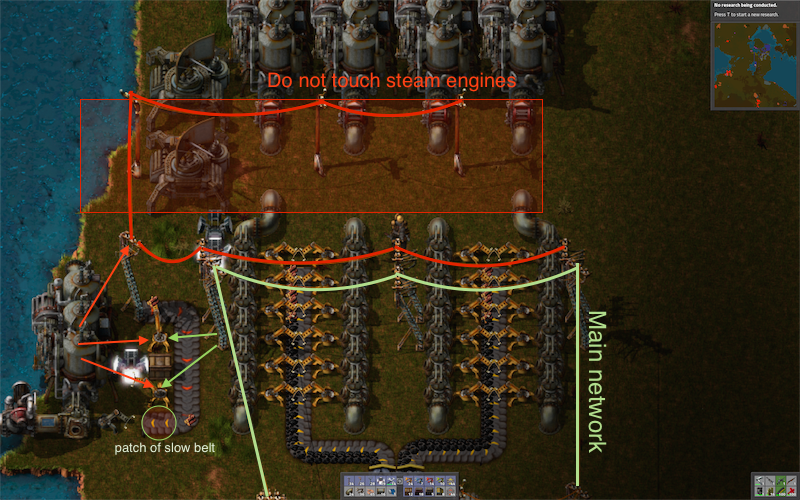

Remade it from scratch for the new big steam engine.

Spent a lot of time on reliability and redundancy, thus it became more complex (lots of manually connected wires)

There was no problems with the old setup, you can use it if you are looking for something simple to quickly hack into your existing powerplant to make your factory greener. Just go with the pump variant, it's more responsive compared to fuel control.

v2

hi-res pic

I don't know the max throughput of the pump, so I used 4.

All inserters that you see are on both networks.

For the wood catching inserter it ensures that there is ALWAYS wood on the belt, so even if the main network is completely dead (for some weird reason I can't even imagine. Short circuit?), main steam engine will keep pumping power into it until it reanimates.

There is no real need to power fuel inserters from both networks, but why not?

Re: Yet another "Steam engine backup" solution (simple&low t

Posted: Thu Nov 13, 2014 1:49 am

by DaveMcW

User_Name wrote:I don't know the max throughput of the pump, so I used 4.

30 water/sec, enough to feed 5 engines and 7 boilers.

If you're trying for fast response time, you can rotate your first inserter 90 degrees to put it closer to the second. Wood planks also have half the energy of raw wood.

Re: Yet another "Steam engine backup" solution (simple&low t

Posted: Thu Nov 13, 2014 4:04 am

by User_Name

DaveMcW wrote:

If you're trying for fast response time, you can rotate your first inserter 90 degrees to put it closer to the second. Wood planks also have half the energy of raw wood.

Thanks for the tip, fixed inserter and made planks.

I guess the shortest possible response time can be achieved by using a car instead of chest for 1 tile travel (parallel inserters), and adding third network consisting of solar panel and capacitor to power inserter that puts wood on the belt and inserter that feeds the boiler (replace burner inserter with fast inserter for less arm travel time, replace both belt inserters with fast inserters for higher "network ping" frequency)

Update: nope, car cannot be used as a chest for fuel. It go into the fuel tank, not cargo.

But replacing all inserters with fast ones improved response time to a fraction of a second.

Re: Yet another "Steam engine backup" solution (simple&low t

Posted: Thu Nov 13, 2014 4:20 am

by CreeperDaReeper

User_Name wrote:Update: nope, car cannot be user as a chest for fuel. It go into the fuel tank, not cargo

Just preload it with a piece of coal, then the planks would go to inventory.

Re: Yet another "Steam engine backup" solution (simple&low t

Posted: Thu Nov 13, 2014 4:31 am

by User_Name

CreeperDaReeper wrote:User_Name wrote:Update: nope, car cannot be user as a chest for fuel. It go into the fuel tank, not cargo

Just preload it with a piece of coal, then the planks would go to inventory.

Nope, doesn't work. Inserter refuses to put fuel items anywhere except the fuel tank.

Anyway, I realized that travel time doesn't affect performance, it's the frequency what matters. Fast inserters is a way to go.

Re: Yet another "Steam engine backup" solution (simple&low t

Posted: Thu Nov 13, 2014 4:45 am

by User_Name

Performance can be further upgraded by adding multiple pairs of fast inserters, but....

Does it really matter anymore?

Re: Yet another "Steam engine backup" solution (simple&low t

Posted: Thu Nov 13, 2014 4:52 am

by User_Name

Just realized that I should measure response time in the midnight, not during the day. In daytime pre-heated water already sits in engines, so the picture really shows nothing.

Re: Yet another "Steam engine backup" solution (simple&low t

Posted: Thu Nov 13, 2014 4:30 pm

by User_Name

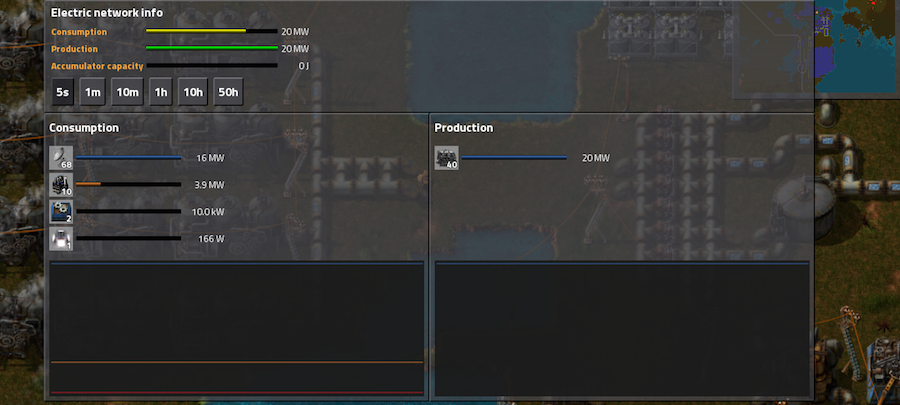

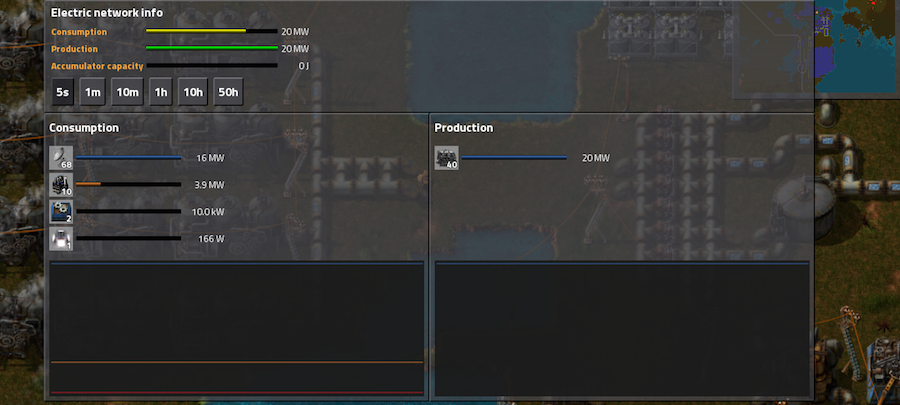

My solar/accu farm can't keep up with the consumption (also, the ratio is wrong)

Steam engine kicks in to help

Re: Yet another "Steam engine backup" solution (simple&low t

Posted: Mon Nov 17, 2014 4:05 pm

by User_Name

More on storing heated water:

You need 14 boilers to heat the water that goes to the tank to 100 degrees.

One water tank stores 210 MJ of energy (that is equal to 42 capacitors, but take much less space)

Normal pipe can supply 10 steam engines with water (edit: it depends on the pipe length,

as explained here)

Pump has half the throughput of the pipe. That allows to use pump as flow limiter, so we can use only 7 boilers to fill hot water tanks.

That works the other way too - with 4 pumps you can have pressurized pipe with double throughput (pipes before the pump are not pressurized, so you still need 2x pipes on the input)

Every port of the water tank has the throughput of a regular pipe, but you can use all 4 at the same time.

Connecting pumps in series doesn't do any good, but connecting them in parallel works.

So, the question is: can we run 40 steam engines with only 2 pipes, single tank and 7 boilers, and still get 20MW?

Yes, we can! (for 11 seconds)

Note the 4 pipes routed from the tank to the pressurization facility. You need 4 on input, 2 on exit.

Re: Yet another "Steam engine backup" solution (simple&low t

Posted: Mon Nov 17, 2014 4:54 pm

by ssilk

User_Name wrote:One water tank stores 210 MJ of energy (that is equal to 42 capacitors, but take much less space)

Sorry for my stupid question, but how have you found that out?

My calculation (

https://forums.factorio.com/wiki/inde ... gy_storage ) is much less (2.5 MJ).

I already thought, that it must be much more.

So - again - I just want to ask how you found that out.

Re: Yet another "Steam engine backup" solution (simple&low t

Posted: Mon Nov 17, 2014 5:18 pm

by User_Name

Placed a hot water tank, small steam engine and 42 capacitors. It charged them to 100% before running dry.

Actually, I double-tested that with 20MW engine from the pic above and got different results - 262MJ (53 capacitors).

Did not expect that much energy from all the extra pipes. That's ~0.8 MJ per pipe, roughly.

That means my calculations above are slightly off, because I did not account for water in the pipes, and I did not remember how many I had used for test setup. Probably none, but I don't remember.